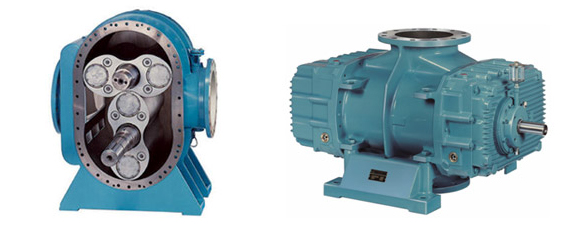

Mechanical booster is often referred to as roots blower, and it exhausts gas emission from

the inlet to the outlet by compression by rotating 2peanut-shaped rotors inside the pump,

while maintaining very small gap with body part. It helps to obtain very high exhaust speed

and is very effective in the pressure range of 50~10-3mbr. Since mechanical booster pump

is used in combination with a pump with low performance, it can greatly improve the

problematic area with low exhaust speed of the pump with low performance and has an

advantage of high efficiency in low vacuum area. In addition, its well balanced rotor in

symmetric structure enables to maintain stability of large products and helps to realize high

capacity performance with less driving force.

01 Excellent mechanical durability

Superior mechanical durability due to the non-contact operation between the screw

and cylinder inside the pump

02 Operational stability

Excellent operational stability and durability due to low-noise and low-vibration

operation by precision machining and balancing

03 Various corrosion resistant coating

Various corrosion resistant coating

04 Excellent discharge capacity

Excellent continuous discharge capacity and continuous operational performance

even in harsh process environment

05 A variety of optional features

Possible to apply flushing, purging and control system options according to the

process characteristics

06 Echo friendly & economical operation

- Economical and eco-friendly dry operation without using water and oil

- Superior efficiency compared to a vacuum pump single model

(degree of vacuum and capacity in relation to power)

07 Flange-type motor with IEC standards

Accurate and easy to assemble due to application of flange-type motor with IEC

standards, and noise reduction realized through the optimal alignment assembly by

machining tolerances

08 Easy maintenance

Easy maintenance and cost savings due to simple structures by optimal design