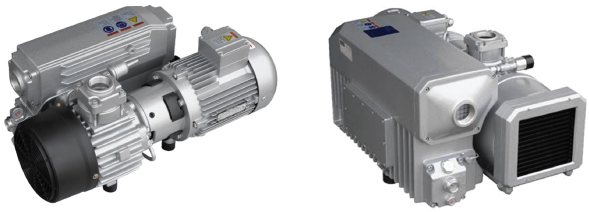

This vacuum pump boasts excellent durability due to simple design equipped with a single

axis and direct driving method , along with low maintenance and operational costs. Its

operation principle is as follows: When the rotor mounted on the inside of the cylinder with

eccentricity and vane inside the rotor make a turn, the vane rotates along the side wall of

the cylinder by centrifugal force, when the gas inhaled in the state sealed by oil supply is

compressed and discharged through the exhaust filter. Oil has a recycled structure, while

implementing sealing and lubrication. The separation oil circulation system in a exhaust part

facilitates its use even in situation in which a large amount of oil vapor occurs at a low

vacuum state. The optional cooling device can be applied in accordance with temperature

conditions around the installed pump or suction processes and used to improve operational

stability of the pump and oil. In addition, the integrated backflow prevention values and

efficient oil filter devices make it possible to conduct suitable configuration using various

accessories. Integrated lubricating oil cooler and standardized circulation-type lubrication

system minimizes noise generation.

01 Durability, noise reduction

Silent operation and improve mechanical durability through direct coupling structure

of the pump and motor and lubricating effect of sealing oil

02Built-in oil circulation device

- preventing oil pollution and consumption of oil due to the built in oil filter and oil

mist filter

- Failure rate reduction and extended pump life

03 A variety of optional features

- Possible to apply various options of suction filter and gas ballast valve according to

process characteristics

- ATEX, Oxygen application

04 Vibration stability

Low vibration realized by the optimal design of cylinder and carbon vane operation

and direct coupling operation

05Abrasion resistance, Reliability of long life

Excellent abrasion resistance through application and design of the optimal special

material vane