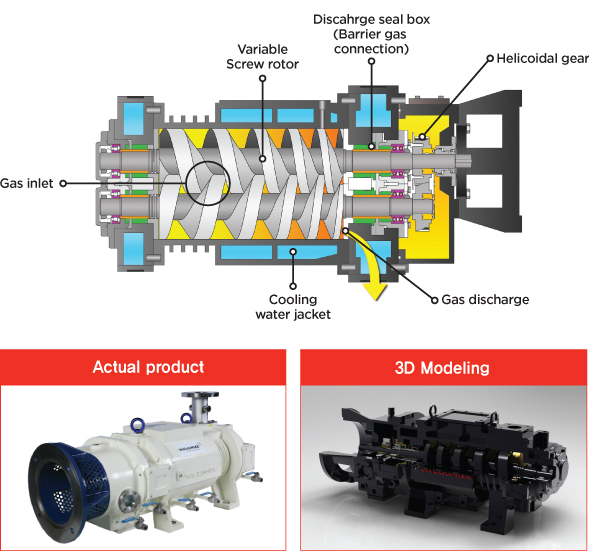

VDP-V model is the latest model that applies a continuous variable screw rotor machined

integrally and improves overall performance efficiency through increased operational

stability and 30% reduction in power energy compared to the existing models with the

same capacity in addition to the advantages of the constant pitch screw. The advanced

integral-type variable screw rotor mechanism ensures performance improvement and

helps to maintain gas flow path and compression process more quickly and reliably,

thereby improving operational stability and durability. The continuous variable screw rotor

design with screw design with a new format boasts more improved capacity to emit water

vapor, liquid and power compared to the existing products, and it enables more stable

operation with low-noise and low-vibration.

01 Excellent durability

- Improved operational stability due to application of integral-type variable screw

- Superior mechanical durability due to the non-contact operation between the screw

and cylinder inside the pump

02Echo friendly & economical operation

- Economical and eco-friendly dry operation without using water and oil

- Energy savings increased by 30% compared to conventional pitch screw

03 Various corrosion resistant coating

Possible to apply various special coating inside the pump to prevent corrosion caused

by process by-products

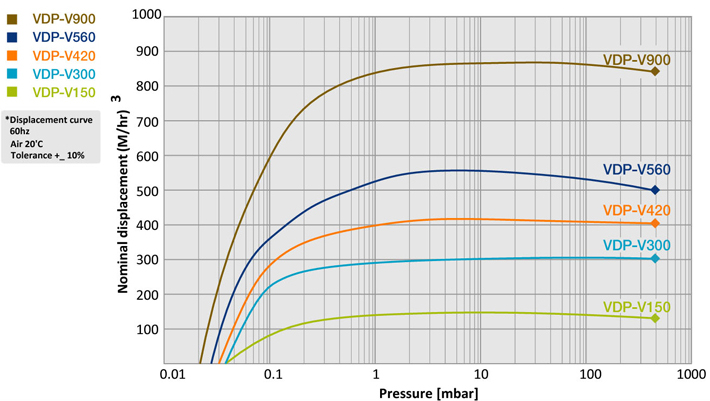

04Excellent discharge capacity

Excellent discharge capacity even in harsh process environment due to variable screw

design of a sing structure with continuity

05 Operational stability

- Excellent operational stability and durability due to low-noise and low-vibration

operation by precision machining and balancing

- Improved operational stability and durability resulting from low operational

temperature reduced by more than 100 °C compared to existing products due to

the increased compression efficiency of integral-type variable pitch screw

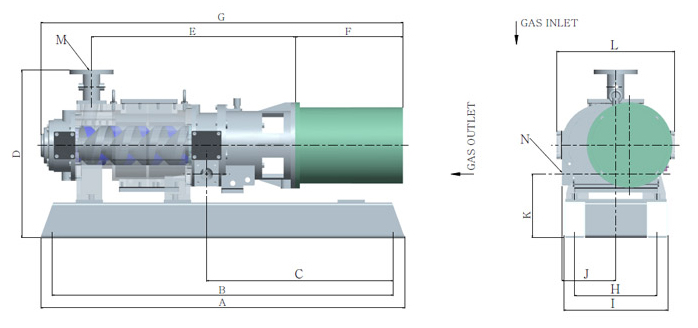

06 Flange-type motor with IEC standards

Accurate and easy to assemble due to application of flange-type motor with IEC

standards and reduction in vibration due to optimal alignment assembling by

machining tolerances

07 A variety of optional features

Possible to apply flushing, purging and control system options according to the

process characteristics

08 Easy maintenance

Easy maintenance and cost savings due to simple structures by optimal design